Automation – Fluid and Gas Handling

General Purpose Valves

Modular valves for different control combinations

Description

The Parker 2 or 3 way valves for all fluids, including air, offer large possibilities to control many kinds of fluids with different sealing and flow capabilities.

According to the installation and requirements, a wide selection of robust valves is proposed to fulfil the most demanding needs.

Typical applications are:

-Shut off valves

-Filling

-Dosing

-Air handling These applications can be found in many markets where reliability and performances are key factors like in industries, process, water treatment, transportation, medical, process, etc…

Key Features

• 3/2, 5/2, 5/3

• 10bar, -20°C to +50°C, up to 3000l/min

• AISI316L St. steel

• 1/4” to 1/2” port size

Customer Benefits

The modular concept of our products, having separate solenoid valves and electrical parts, provides the customer with increased flexibility by allowing numerous combinations. This additional flexibility can enable distributors to greater reduce valve inventory levels, whilst retaining the same number of capabilities. Parker also has unrivalled experience in developing customised product solutions complying with the highest technical, environmental, energy and service life requirements.

Namur Valves

Accurate control in safe and dangerous areas

Description

Control of single or double acting pneumatic actuators, in safe or dangerous areas.

The interface design is conform to the NAMUR standard and to the VDI/VDE 3845 recommendations of the actuator industry. It allows a compact design of the actuator/valve unit. In case of a 3/2 function, the air of the actuator spring chamber also flows through the pilot valve (re-breather function). This prevents corrosion of the actuator springs.

Key Features

• All fluids and air, water, hot water and steam

• 2 way, 3 way & 5 way – normally closed, normally open, universal, dual solenoids

• Direct operated, pilot operated, magnalift, air operated

• 1/8” to 1 ¼”

• Brass, 316L St Steel, anodized aluminium

Customer Benefits

• High flow : 1.250 l/min (1/4″), 3.000 l/min (1/2″)

• Compact design

• Long life expectancy

• Coil Modularity: a large part of the range is compatible with different type of coils, ATEX, non ATEX and Low Power

• Fail safe standard

• Reduced inventory (3/2 & 5/2 functions with the same valve on 341Nx5 series)

• Mechanical part of the valve ATEX certified according standard EN 13463-1 & -5 (with maximum capability of zone 1-21 )

Angle Seat Valves

Durability in aggressive and steam applications

Description

An Angle Seat Valve is actuated by a pneumatically driven piston and is capable to handle slurry solutions with particles or corrosive fluids at high temperature up to 180°C and operating pressure up to 16 bar, thanks to its high-grade 316 st.steel and PTFE seals. Compliance to Explosive Atmosphere (zones 1/21 and 2/22) as well as a visual position indicator are provided as standard.

3/2 way direct acting AC/DC Pilot Control Valves are available as separate components from the large assortment provided by Parker FCDE.

Key Features

• 2/2 way normally open or closed

• 16bar, 180°C, DN10-DN62

• 304/316 st.steel

• 3/8” to 2 ½” port size

Customer Benefits

• Full stainless steel body and actuator as standard

• ATEX zone 2 approved

• Interchangeable with competition

• Compact design for easy integration

• Visual position indicator

201LG Stainless Steel Valves

High grade corrosion resistant valve for a wide range of applications

Description

High-grade material and corrosion resistant 201, 202, 301LG Valve Series is a complete range of 2 way and 3 way valves, direct acting, normally close and normally open.

This new range of solenoid valves, having AISI316L grade stainless steel body, is the right answer for a wide range of applications in Food & Beverage Industry, Process industry, Wastewater treatment appliances, Marine, high temperature steam applications in aggressive environments or with aggressive media.

FFKM seals option is available in order to increase mechanical, high temperature and aggressive media resistance for the most specific and demanding fluid control applications.

Thanks to the modular concept, a wide range of electrical parts can be used including ATEX, IP67, H class, reduced power, UL or VDE approved.

A wide selection of valves is also NSF certified; please consult Parker documentation to find out the NSF certified models. Mechanical ATEX approval is available.

Key Features

• 2 way normally closed or open, 3 way normally closed

• Up to 20bar, 180°C, orifice diam. up to 6,2mm

• 316L St. steel

• 1/8” to 1/2” port size

Customer Benefits

• High grade corrosion resistant valve body, AISI316L

• NSF certified references available, please consult Parker documentation in order to find out NSF certified options.

• FFKM seal option for superior endurance in heavy duty conditions

• Modular concept: a wide range of electrical parts can be used with this family, including ATEX, low power, IP67, UL/VDE approved • Robust and solid design

Cartridge Solenoid Valves

2-Way and 3-Way – Series C07/C15/C21 (for industrial applications)

Description

These new 2 & 3 way cartridge valves offer the most compact solution. Easy to integrate, these solenoid valves can be populated into the smallest portable devices improving performance, size and weight. This range is available in 3 sizes (7, 15 & 21 mm) with a wide range of orifices (0,3 to 4 mm).

Benefits

• Customizable – can be adapted to the application : voltage, flow, shape, material, cable length, connection, proportional version…

• Easy to embed – reduce integration cost thanks to the cartridge concept

• Compact – 80% reduction of volume vs standard threading solenoid valves

• Improve mobility/portability – 80% reduction in weight vs standard threading solenoid valves

• Save cost – very low power (0,5 to 2,5W) decreasing the size of your battery and the energy consumption

• Long service life – > 109 cycles according application thanks to the frictionless design

• Increase productivity – fast response time (from 0,5 to 7 ms)

Cartridge valves are suitable for many process and industrial applications

• High grade corrosion resistant valve body, AISI316L

• NSF certified references available, please consult Parker documentation in order to find out NSF certified options.

• FFKM seal option for superior endurance in heavy duty conditions

• Modular concept: a wide range of electrical parts can be used with this family, including ATEX, low power, IP67, UL/VDE approved • Robust and solid design

Electronic Proportional Pressure Regulator

Fast and accurate pressure control in severe environments

Description

EPP4 is an electro-pneumatic pressure regulator with an integrated electronic system.

Two pulsed width modulated solenoid valves control the output pressure proportionally to an analogue input signal. Very high accuracy is guaranteed thanks to a high precision closed loop signal provided by a built in pressure sensor.

Designed to work in harsh environments it can also be produced for Explosive Atmosphere as well as for Oxygen use.

Key Features

• Closed loop integrated electronic control

• 0-10V or 4-20 mA control signal

• 10 (20) bar max, 50mbar hysteresis

• IP65 for severe environments

• ¼” to 2” port size

Customer Benefits

• Integrated electronics & software

• Setting adjustments via PC (free software)

• Suitable for harsh environment and unfiltered air

• No air consumption at constant signal

• Compact, light, low power, long life expectancy

• Application specific electronic controls on request

Ionized spot pulse blow remove strong electrified dust and prevent static electrified dust accumulation effectively!

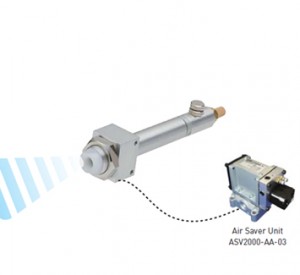

Spot Ionizer ESN-200 (applicable to pulse blow)

Nozzle type Spot Ionizer dis-electrify the static electrified point at a pin point by using compressed air.

Possible to install Spot Ionizer near the target point thanks to high performance ion balance, +/-10V, in 28mm

width compact body.

The combination usage with ” Air Saver Unit” makes ionized blow as pulse and reduces approximately 50% compressed

air consumption.

● High frequency AC discharge system creates stable ion balance.

● Built-n control circuit board in 28mm width compact body.

● Selectable from straight and elbow style nozzle.

● Two color LED indicate normal or abnormal operation.

● Daisy-chain connection makes multiple Spot Ionizers usage easy.

Jets out Cold Air (Maximum -60℃)than inlet air only by supplying compressed air!

Long life. No electricity or refrigerant is necessary.

Spot Cooler (cold air generator) PJC series

Spot Cooler is a cold air generator (vortex tube) that apply the principle of vortex theory.

Compressed air is whirled in high speed inside Spot Cooler and separates cold and hot air.

Spot Cooler does not have moving part, and refrigerant and electricity are not necessary.

It can be used not only for spot cooling by cold air but also warming up by hot air.

The combination usage with “Air Saving Unit” that compensates energy saving,

would be possible to reduce approximately 50% of air consumption.

Feature

● Electricity is not necessary

● Compact, light weight and easy installation

● Long life

● Air temperature adjustable by adjusting screw

Water Retract Actuator

Parker in Automotive Industry

Parker is committed to offering the Automotive Industry the most comprehensive array of motion control products

and technologies. Parker is continuously improving the performance and value of our products and services

to meet current and future needs of the global Automotive Industry. Parker Automotive manufacturing focus

includes body and assembly, power train, metal stamping, components and trim.

Overview

Water Retract Actuator is a solution designed to

prevent excessive water spillage during the routine tip

change of a spot welding gun.

Excessive water spillage within a weld cell environment

presents a number of hazards including, electrical

shock, slip hazard, equipment damage, and damage

to the product that is being manufactured.

The Water Retract Actuator reduces the water pressure

in the closed-off cooling circuit which eliminates the

problems of water being expelled under pressure

during a tip change.

Sinclair Collins Valves: Designed for High Performance

Sinclair Collins has been designing and manufacturing process control valves for a va-

riety of industries. The rugged design and reliability of the K Series valves make them ideally suited for a

variety of applications requiring the control of steam, gas, liquids or chemicals. All components must meet

our high performance specifications and quality control standards. Prior to shipment, every valve is fully

tested to assure the quality that is expected from Sinclair Collins.

Technical Specifications

• Maximum media pressure = 250 PSI(2″ valve maximum = 230 PSI)

• Body sizes 1/2″, 3/4″, 1″, 1¼”, 1½”, 2″

• -40°F to 400°F (-40°C to 204°C) maximum temperature

• Actuator is field reversible, air to open, air to close

• Rolling style diaphragm provides uniform thrust

• Three actuator sizes: 37, 64, 135. Maximum 35 PSI on 37 and 64 sizes; maximum 25 PSI on 135 size.

• Stem diameter 7/16″

• Stem travel (stroke) 0.75″ all sizes

• Multi-spring, low-profile actuators offer a 12 PSI control band. Other options available.

• 100% nitrogen gas tested

• Hard seat meets Class IV leakage standards

Parker Level Switch

Pneumatic Technology Products

Features

• A compact type product that can be easily maintained and repaired in small spaces

• Optimum for controlling powders and fine particles such as flour, wheat flour, sugar, and plastic materials

• Highly sensitive with built-in springs that can be adjusted to four levels

• Usable in various kinds of small hoppers such as grain tanks and rice husk tanks

파카 산업용솔레노이드밸브 범용제품 가이드

단납기 대응 제품

파카 산업용솔레노이드밸브 유럽생산

(LUCIFER , SEAM )

파카 산업용솔레노이드밸브 USA 생산

(SKINNER, GOLD RING)

Parker 인증 제품 및 인증서

• CE , UL , AGA , RoHS , IECEx , TR CU , TUV , GOST

• NSF , ATEX , Kosha , VDE , Reach , CSA , DIN , IMQ

• EXIDA 인증 제품

• Dow Chemical 사용제품

인증관련 제품은 보광유공압에 문의 바랍니다.