For life Sciences, Food & Beverage and General Purpose applications

생명 과학, 식음료 그리고 범용으로 최적화 된 201/202/301LG Series (스테인레스 스틸 솔레노이드 밸브)

Product Description

High grade material and corrosion resistant 201, 202, 301LG Valve Series is a complete range of 2 way and 3 way valves, direct acting, normally close and normally open.

This new range of solenoid valves, having AISI316L grade stainless steel body, is the right answer for a wide range of applications in Food & Beverage Industry, Process industry, Wastewater treatment appliances, Marine, high temperature steam applications in aggressive environments or with aggressive media.

FFKM seals option is available in order to increase mechanical, high temperature and aggressive media resistance for the most specific and demanding fluid control applications.

Thanks to the modular concept, a wide range of electrical parts can be used including ATEX, IP67, H class, reduced power, UL or VDE approved.

A wide selection of valves is also NSF certified; please consult Parker documentation to find out the NSF certified models. Mechanical ATEX approval is available.

Market of interest:

● Life Sciences

● Food & Beverage Processing

● Commercial Equipment

● Industrial equipment

● Waste Water treatmentApplications

Typical applications can be found in:

● Water purification and preparation devices

● Food & Beverage processing, Healthy Beverage Dispense equipment

● Demineralized water shut off, cooling of medical and surgical devices

● Dishwasher disinfectors, Laboratory and high end hot steam sterilizers

● Aggressive liquids shut-off

● Ammonia (with silver shading ring version)

Benefits:

The most valuable features you will find in this product range

● High grade corrosion resistant valve body, AISI316L

● NSF certified references available, please consult Parker documentation in order to find out NSF certified options.

● FFKM seal option for superior endurance in heavy duty conditions

● Modular concept: a wide range of electrical parts can be used with this family, including ATEX, low power, IP67, UL/VDE approved

● Robust and solid design

General Description

Material Specifications

Valve Body: AISI316L Machined Stainless Steel

Pilot tube: AISI 303 Stainless Steel

Plunger: AISI 430F Stainless Steel

Spring: AISI 302 Stainless Steel

Seals: FKM, FFKM

Nozzle: AISI316L

Shading ring: Copper OR Silver, according to selected version

Installation

The valves can be mounted in any position. It is however recommended to install them with the coil invertical position above the body.

Coils

A wide range of coils can be used with this range.

Media

These valves have been developed to achieve the best performances with a wide range of media.

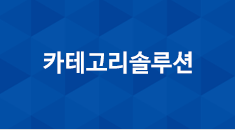

밸브 바디 (Valve body) 선정표

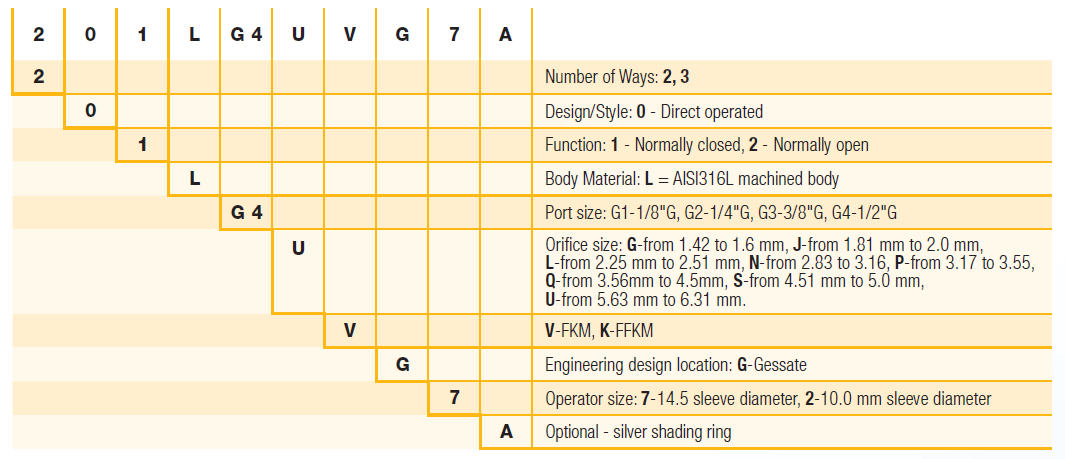

사용 유체 호환 차트 (Fluid Compatibility Chart)

카탈로그에 명기된 각 밸브 별 Compatibility Class 가 A 인지 B 인지 C 인지를 확인하시어 해당 유체를 매치하여 확인

별도 명시 없는 한, 100% 동일 유체, 주위 온도 25° C

NR = Not recommended (추천하지않음) S = Satisfactory (만족) NA = Data not available (데이터없음)

| Port Size | Orifice Ø | Flow Factors | Operating Pressure Differential | Fluid Temperature | Seat Seal | Parker Valves | Power | Coil Group | Fluid Compatibility Class | Drawing N° | ||||||

| BSP | mm | kv l/m | Kv m3/h | Min Bar | Max Bar(MOPD) AC | Max Bar(MOPD) DC | Min °C | Max °C | Valve | Coil | AC W | DC W | ||||

| 1/4″ | 3 | 4.5 | 0.27 | 0 | 6 | 6 | -10 | 140 | FKM | 202LG2NVG7 | D5 | 8 | 9 | 24/2.0 | A | 3 |

| 5 | 8 | 0.48 | 0 | 3 | 3 | -10 | 140 | FKM | 202LG2SVG7 | D5 | 8 | 9 | 24/2.0 | A | 3 | |

| 1/2″ | 5 | 8 | 0.48 | 0 | 3 | 3 | -10 | 140 | FKM | 202LG4SVG7 | D5 | 8 | 9 | 24/2.0 | A | 3 |

| 6.2 | 10 | 0.6 | 0 | 1 | 1 | -10 | 140 | FKM | 202LG4UVG7 | D5 | 8 | 9 | 24/2.0 | A | 3 | |

| Port Size | Orifice Ø | Flow Factors | Operating Pressure Differential | Fluid Temperature | Seat Seal | Parker Valves | Power | Coil Group | Fluid Compatibility Class | Drawing N° | ||||||

| BSP | mm | kv l/m | Kv m3/h | Min Bar | Max Bar(MOPD) AC | Max Bar(MOPD) DC | Min °C | Max °C | Valve | Coil | AC W | DC W | ||||

| 1/8″ | 1.5 | 1 | 0.06 | 0 | 16 | 7 | -10 | 140 | FKM | 201LG1GVG2 | DF | 2 | 2.5 | 1.1/1.3 | A | 1 |

| 1.5 | 1 | 0.06 | 0 | 20 | 15 | -10 | 140 | FKM | 201LG1GVG2 | DG | 4 | 5 | 1.1/1.3 | A | 1 | |

| 2.5 | 2.3 | 0.14 | 0 | 8 | 3 | -10 | 140 | FKM | 201LG1LVG2 | DF | 2 | 2.5 | 1.1/1.3 | A | 1 | |

| 2.5 | 2.3 | 0.14 | 0 | 10 | 6 | -10 | 140 | FKM | 201LG1LVG2 | DG | 4 | 5 | 1.1/1.3 | A | 1 | |

| 1/4″ | 1.5 | 1 | 0.06 | 0 | 16 | 7 | -10 | 140 | FKM | 201LG2GVG2 | DF | 2 | 2.5 | 1.1/1.3 | A | 1 |

| 1.5 | 1 | 0.06 | 0 | 20 | 15 | -10 | 140 | FKM | 201LG2GVG2 | DG | 4 | 5 | 1.1/1.3 | A | 1 | |

| 2.5 | 2.3 | 0.14 | 0 | 8 | 3 | -10 | 140 | FKM | 201LG2LVG2 | DF | 2 | 2.5 | 1.1/1.3 | A | 1 | |

| 2.5 | 2.3 | 0.14 | 0 | 10 | 6 | -10 | 140 | FKM | 201LG2LVG2 | DG | 4 | 5 | 1.1/1.3 | A | 1 | |

| Port Size | Orifice Ø | Flow Factors | Operating Pressure Differential | Fluid Temperature | Seat Seal | Parker Valves | Power | Coil Group | Fluid Compatibility Class | Drawing N° | ||||||

| BSP | mm | kv l/m | Kv m3/h | Min Bar | Max Bar(MOPD) AC | Max Bar(MOPD) DC | Min °C | Max °C | Valve | Coil | AC W | DC W | ||||

| 1/4″ | 1,5 | 1,0 | 0,06 | 0 | 20 | 15 | -10 | 140 | FKM | 201LG2GVG7A | D4 | 9 | 8 | 24/2.0 | 2 | |

| 1.5 | 1 | 0.06 | 0 | 20 | 15 | -10 | 180 | FFKM | 201LG2GKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 3 | 4.5 | 0.27 | 0 | 9 | 5 | -10 | 140 | FKM | 201LG2NVG7 | D4 | 9 | 9 | 24/2.0 | A | 2 | |

| 3 | 4.5 | 0.27 | 0 | 9 | 5 | -10 | 140 | FKM | 201LG2NVG7A | D4 | 9 | 9 | 24/2.0 | B | 2 | |

| 3 | 4.5 | 0.27 | 0 | 20 | 8 | -10 | 140 | FKM | 201LG2NVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 3 | 4.5 | 0.27 | 0 | 20 | 8 | -10 | 140 | FKM | 201LG2NVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 3 | 4.5 | 0.27 | 0 | 9 | 5 | -10 | 180 | FFKM | 201LG2NKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 3 | 4.5 | 0.27 | 0 | 20 | 8 | -10 | 180 | FFKM | 201LG2NKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 4 | 7 | 0.42 | 0 | 5 | 3 | -10 | 140 | FKM | 201LG2QVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 | |

| 4 | 7 | 0.42 | 0 | 5 | 3 | -10 | 140 | FKM | 201LG2QVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 | |

| 4 | 7 | 0.42 | 0 | 10 | 4 | -10 | 140 | FKM | 201LG2QVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 4 | 7 | 0.42 | 0 | 10 | 4 | -10 | 140 | FKM | 201LG2QVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 4 | 7 | 0.42 | 0 | 5 | 3 | -10 | 180 | FFKM | 201LG2QKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 4 | 7 | 0.42 | 0 | 10 | 4 | -10 | 180 | FFKM | 201LG2QKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG2SVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG2SVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG2SVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG2SVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 180 | FFKM | 201LG2SKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 180 | FFKM | 201LG2SKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG3SVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 | |

| 3/8″ | 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG3SVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG3SVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG3SVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 180 | FFKM | 201LG3SKG7 | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 180 | FFKM | 201LG3SKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 140 | FKM | 201LG3UVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 140 | FKM | 201LG3UVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 140 | FKM | 201LG3UVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 140 | FKM | 201LG3UVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 180 | FFKM | 201LG3UKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 180 | FFKM | 201LG3UKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 1/2″ | 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG4SVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 140 | FKM | 201LG4SVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG4SVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 140 | FKM | 201LG4SVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 5 | 8 | 0.48 | 0 | 3 | 2 | -10 | 180 | FFKM | 201LG4SKG7 | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 5 | 8 | 0.48 | 0 | 8 | 2.5 | -10 | 180 | FFKM | 201LG4SKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 140 | FKM | 201LG4SVG7 | D4 | 9 | 8 | 24/2.0 | A | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 140 | FKM | 201LG4UVG7A | D4 | 9 | 8 | 24/2.0 | B | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 140 | FKM | 201LG4UVG7 | DM | 14 | 14 | 24/2.0 | A | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 140 | FKM | 201LG4UVG7A | DM | 14 | 14 | 24/2.0 | B | 2 | |

| 6.2 | 10 | 0.6 | 0 | 1.5 | 0.5 | -10 | 180 | FFKM | 201LG4UKG7A | D4 | 9 | 8 | 24/2.0 | C | 2 | |

| 6.2 | 10 | 0.6 | 0 | 4 | 1.5 | -10 | 180 | FFKM | 201LG4UKG7A | DM | 14 | 14 | 24/2.0 | C | 2 | |

| Fluid |

| ACETONE |

| ACETYLENE, DRY |

| ACID BORIC |

| ACID CHROME |

| ACID CITRIC |

| ACID HYDROCHLORIC |

| ACID LACTIC |

| ACID PHOSPHORIC |

| ACID PICRIC |

| ACID SALICYLIC |

| AIR, HOT |

| AIR, UNLUBRICATED |

| ALCOHOL AMYL |

| ALCOHOL BUTYL |

| ALCOHOL ETHYL |

| ALCOHOL METHYL |

| ALCOHOL PROPYL |

| AMMONIA, GAS (ANHYDROUS) |

| ARGON |

| BENZINE (LEADED AND UNLEADED) |

| CHLOROFORM |

| CIDER |

| COFFEE |

| CYCLOHEXANE |

| ETHYLENE GLYCOL |

| FIRE RESISTANT NON AQUEOUS HYDRAULIC |

| FLUID |

| FIRE RESISTANT OIL IN WATER EMULSIONS |

| FIRE RESISTANT WATER IN OIL EMULSIONS |

| FIRE RESISTANT WATER GLYCOL SOLUTIONS |

| FOOD PRODUCTS |

| HELIUM |

| KEROSENE JP-1 TO JP-3 |

| LEMON AND ORANGE JUICE |

| MERCURY |

| NAPHTA |

| NITROGEN |

| OIL ANIMAL OIL |

| OIL ASTM OIL 1,2,3 |

| OIL DIESEL |

| OIL SETABLE |

| OIL EXTRA |

| OIL FUEL |

| OIL GREASING |

| OIL HEAVY |

| OIL SILICONE |

| OIL TRANSFORMER |

| OIL VEGETABLE |

| OZONE GAS/LIQUID |

| PERCHLORETHYLENE |

| PHENOL |

| POTASSIUM SULFATE |

| SOAPY WATER |

| SODIUM HYDROXIDE |

| TOLUENE (TOLUOL) |

| TRICHLORETHYLENE |

| TURPENTINA |

| WATER |

| WATER DEIONISED/DISTILLED |

| WATER DEMINERALISED |

| WATER DRINKABLE |

| WATER HOT |

| WATER OXYGENATED |

| WATER SEA |

| XYLENE |

![[Parker] Miniature Solenoid Valves 파카 미니어처 소형 솔레노이드 밸브](http://bkvalve.co.kr/bk/wp-content/uploads/2024/08/Solenoid-valve1.png)