2/2 WAY & 3/2 WAY 밸브 – 파일롯 오퍼레이트

파이프 배관 (G 1/2-3/4) 또는 베이스 배관

1.5 – 40 BAR

상시 닫힘 또는 상시 열림

내부 또는 외부 파일럿 압력 공급

Product offering:

● 2/2 valves and 3/2 way valves – pilot operated

● Pipe mounting (G 1/2- 3/4) or sub-base mounting

● 1.5 (2) – 40 bar

● Normally open or closed

● Internal or external pilot pressure supply

Customer Value Proposition:

● Safety of operation

● Reliability

● Response time stability

● Repeatability

● No leakage

● Integrated non return valve (421version)

Plastic Bottle Blowing

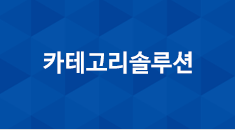

Fig.1

Three valves (F type) are grouped on a common block to assure the above mentioned operation.

Three 2-way solenoid valves permit to control the required blowing functions to produce plastic bottles.

In a first phase the N.O. valves (322 H 35) and N.C. valves (421 H 35) are energised. The pressure in the circuit is therefore established to a pre-determined level (2 to 15 bar). During the same time the 3/2 valve

(331 B 31) maintains the mould closed with a 40 bar pressure. In a second phase, the N.C. valve 321H35 is energised and the pressure increases up to 40 bar. Independently from the position of the 421H35 valve, the 321H35 valve assures by design that the 40 bar pressure is maintained and cannot go back into the “low pressure” circuit. In a third phase, the N.O. valve 322H35 is de-energised and permits the discharge of the circuit down to 0 bar.

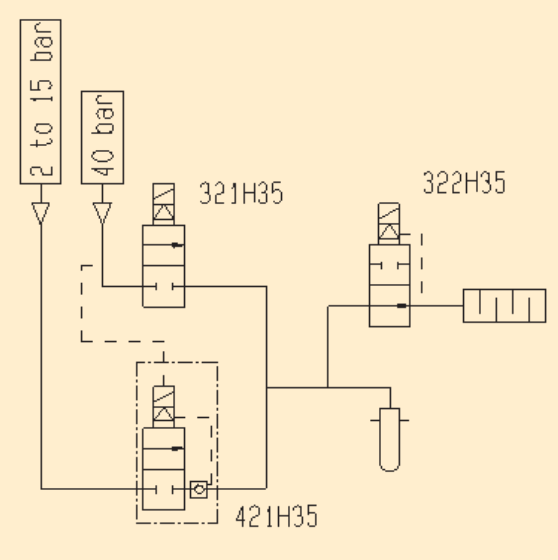

Laser Cutting

For this application, few 2/2 Normally closed valves control the gas inlet, in order to assure the different phases and options of the laser cutting. The valves 321H35 are used for inert gases as Air, Argon, Nitrogen.

A special model 321HS… is used for oxygen applications. Electronic pressure regulators type EPP… regulate the pressure from 0 to 20 bar, according to cutting conditions.

![[Parker] Miniature Solenoid Valves 파카 미니어처 소형 솔레노이드 밸브](http://bkvalve.co.kr/bk/wp-content/uploads/2024/08/Solenoid-valve1.png)